Automotive OEMs need to reduce the carbon emissions of their vehicles by an average of 30 percent up to 2030. Now the world is awaiting the advent of the mass-produced electric car. It is still unclear how the high demand for lithium batteries will affect the environment. Moreover, scientists agree that heavy trucks, ships, aircraft and construction machinery will not work with electric motors in the long term. However, there is already an alternative clean fuel: E-fuel. It has been almost completely drowned out by the euphoria surrounding electric drive trains. This article explains what e-fuels are and why they deserve greater attention.

E-fuels are artificially produced fuels

E-fuels are liquid fuels that chemists can produce using (green) electricity, water and carbon dioxide. E-fuels can replace petrol, diesel and kerosene in various forms and have the same chemical properties as the “original” derived from a conventional petroleum refinery. E-fuels have the advantages of liquid fuels that have proven themselves over decades – but are not distilled from petroleum.

E-fuels are precisely the same as petroleum-based fuels but burn even more cleanly and efficiently

The diesel and petrol fuels derived from petroleum and chemically produced e-fuels are so similar that users can store the products in the same tanks, use them in the same vehicles and refuel from the same fuel pumps. Because E-fuels are also purer than fossil fuels due to their synthetic production, they burn more efficiently. But there is another big advantage to E-fuels:

How E-fuels are produced: the process is known as “power to liquid”

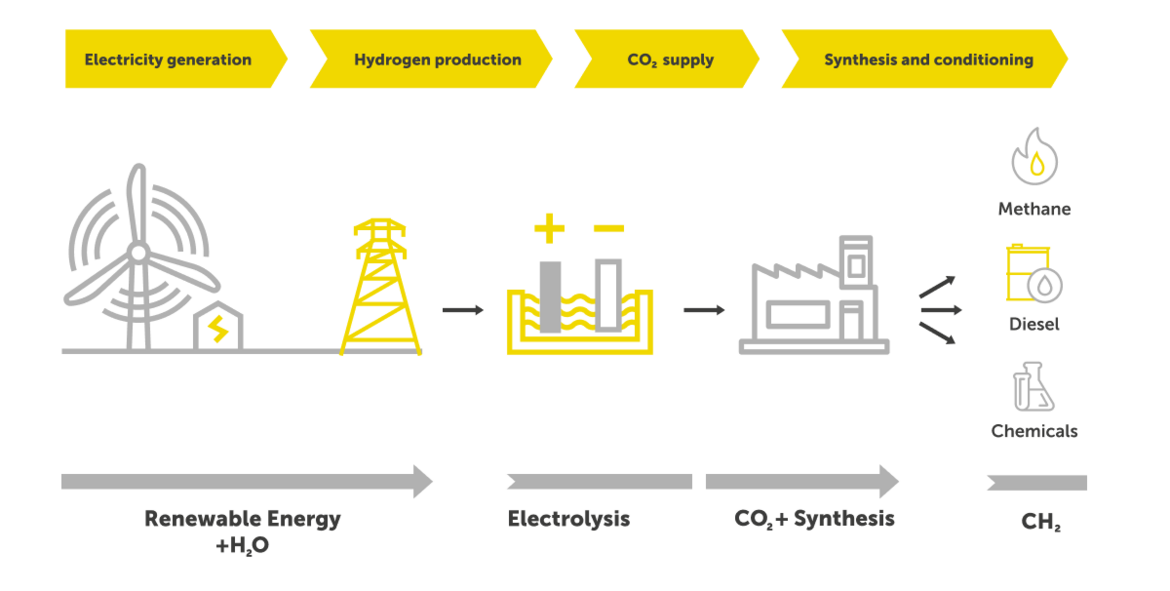

E-fuels are produced in a specific chemical reaction. These are the two general steps:

- Electrolysis splits water molecules (H2O) into hydrogen (H2) and oxygen (O2).

- The resultant hydrogen then reacts with CO2 and is combined with its building blocks to form hydrocarbons. Known as Fischer-Tropsch synthesis, this process uses hydrogen as a storage medium for energy.

There is some variation in the details of production and the product is not yet ready for the market. However, as of 2019, all e-fuels are derived from electrolysis. CO2 can be extracted directly from the atmosphere using innovative technologies or is produced as a by-product in industrial processes. If companies also produce the fuel using renewable energies, the result is a completely climate-neutral energy source. The term “power-to-fuel” has become established as this chemical process transforms electricity into liquid fuel.

Investment incentives for power to liquid? There is still no institutional recognition of E-fuels.

They currently do not count towards automotive OEMs’ emission targets, meaning that they cannot be used to achieve the crucial CO2 fleet limits. This makes major investments in this technology unattractive, forcing many OEMs to focus on the e-car. Greater technological acceptance would strengthen Germany as a technology hub and create new jobs.

E-fuels use the existing infrastructure and application technologies for liquid energy carriers

E-fuels are in danger of being drowned out by the hype surrounding electromobility. But 98 percent of the total energy required for propulsion in the transport sector is dependent on liquid fuels. Millions of these vehicles are in operation and will not vanish over night – whether we like it or not. The main and understandable argument against the hydrogen cell and electromobility is the absence of the necessary infrastructure, which also happens to be very expensive. E-fuels solve this problem because the existing infrastructure, including tank farms, pipelines, vehicle fleets and filling stations can be used almost completely.

Power to liquid makes it possible to store and transport regenerative energies more readily

Unlike electricity, E-fuels can be transported using tanker trucks and ships instead of batteries. Batteries are not only expensive to produce, but also require lithium. Massive lithium mining can severely harm the environment, both through damage to the landscape and via greenhouse gases. In addition, batteries do not last forever and very large capacities pose problems. This results in large quantities of hazardous waste or very expensive recycling processes.

E-fuels solve the problem of many solar and wind power plants by enabling them to transport electricity in liquid form. For many years it has been clear that people in North Africa, Patagonia and Australia could generate huge amounts of renewable energies from solar energy and, in coastal areas, from wind energy.

The consequence: E-fuels kill many birds with one stone

E-fuels from renewable energies are carbon-neutral, soot-free and therefore pose no health risks, plus which they use the existing tank and storage infrastructure. They make wind and solar energy more efficient. However, they are still comparatively unknown and this is something we want to change. Granted, producing E-fuels is still quite a complex process. Conversion losses and operating costs are high because production has not yet reached a sufficient state of maturity. This is why companies and research institutions need more incentives to systematically develop E-fuels and make them usable. One side effect of a hydrogen electrolysis industry is the resultant creation of jobs and additions to the domestic value chain.

So, our hope is that the government will soon be paying more attention to E-fuels. This is not a question of pitting electric motors against E-fuels, but of coming up with a viable energy mix.

![[Translate to English:] Tanklastwagen](/fileadmin/_processed_/b/c/csm_header-img-artikel10_55d60816ba.jpg)

![[Translate to English:] DS Tank](/fileadmin/_processed_/f/c/csm_artikel10_0db6c110e8.jpg)